| Selected Metric Threads | ||||||

|---|---|---|---|---|---|---|

| Diameter | Coarse Pitch | Fine Pitch | "Common" hex (wrench) size | |||

| 6 | 1.0 | 10 mm | ||||

| 8 | 1.25 | 1.0 | 12 or 13 mm | |||

| 10 | 1.5 | 1.25 | 14, 15, 16, or 17 mm | |||

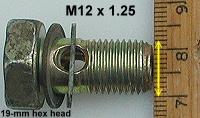

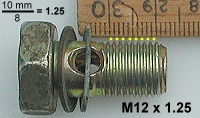

| 12 | 1.75 | 1.25 (1.50) | 17, 18, or 19 mm | |||

| 14 | 2.0 | 1.5 | 21 or 22 mm | |||

| 16 | 2.0 | 1.5 | 24 mm | |||

| 18 | 2.5 | 1.5 | 27 mm | |||

| 20 | 2.5 | 1.5 | 30 mm | |||