| |

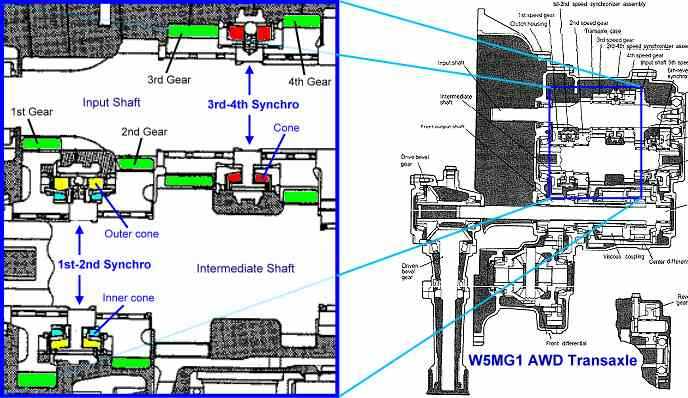

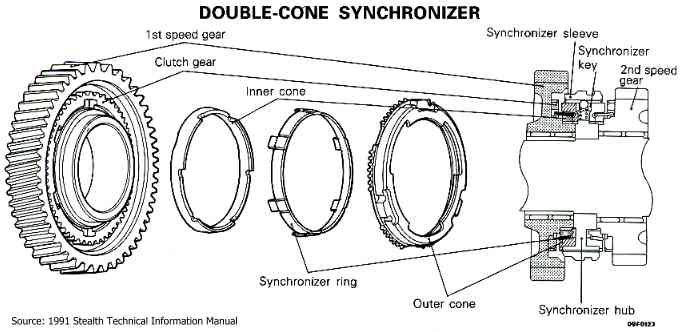

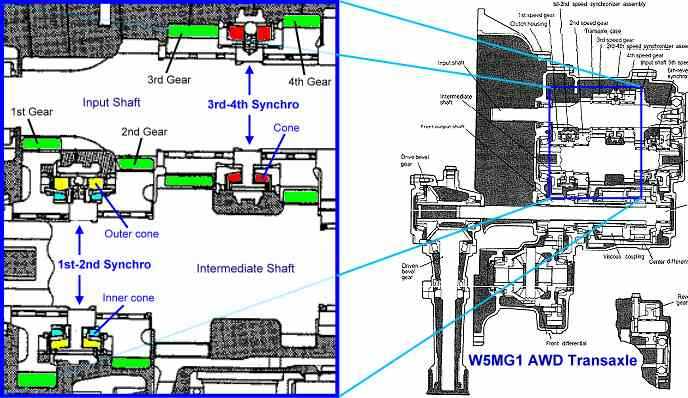

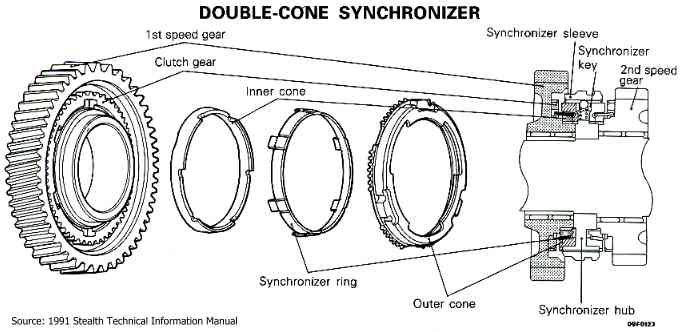

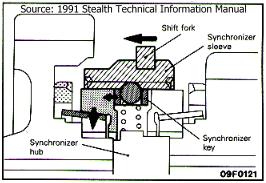

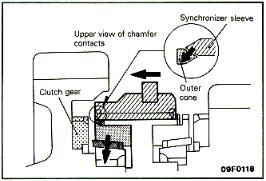

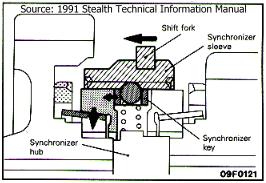

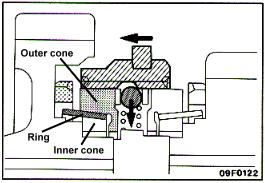

The shift fork moves the synchro sleeve to the left when the shift lever is moved toward first speed. Because the ball in the synchro key is pressed into the sleeve by the spring, the synchro sleeve and key are joined and move to the left. |

| |

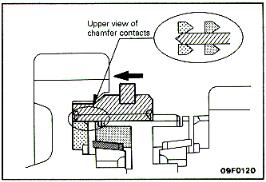

As the shift fork continues to move to the left, the sleeve pushes the ball down into the key, then crosses over the key. |

| |

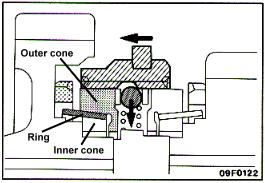

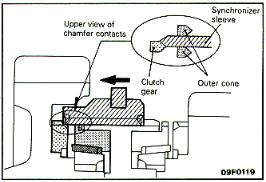

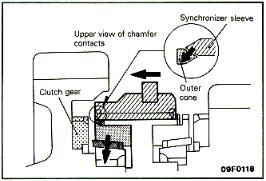

At this point, the chamfer of the outer cone spline and the chamfer of the sleeve spline come into contact. As a result of this contact, a pushing force is generated in the outer cone. As the friction torque increases between the ring and outer and inner cones, the difference in rotation speed of the 1st-speed gear and synchronizer hub reduces. |

| |

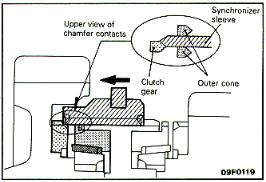

The shift fork continues to press the synchronizer sleeve to the left and the sleeve spline and outer cone spline mesh, that is, the outer cones moves "into" the sleeve. |

| |

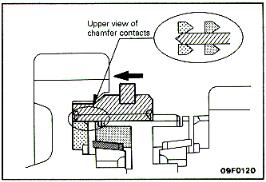

As the sleeve continues to move to the left, the sleeve spline chamfer comes into contact with the clutch gear chamfer. The clutch gear spline and synchronizer sleeve spline mesh to complete the shift to 1st speed. |