|

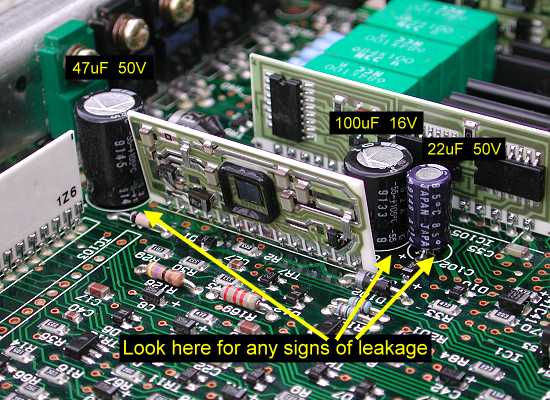

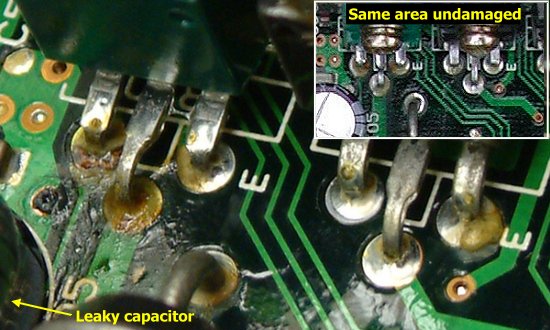

Simple visual inspection will not always reveal the leaking capacitor more often than not.

The only 3/S ECU's that do not have this problem is the 98/99 ECU's in the black plastic case as they use SMT NON-Electrolytic caps. Every other year is at risk and will leak, it is only a matter of time, as well as those already replaced. This is a known issue with electrolytic caps (short lifespan), not our ECU's or any other design concern. Electrolytic capacitor life is most often rated in hours at a set temperature. For example, typically as 2000 hours at 105 degrees Celsius (which is the highest working temperature). Sorry to be the bearer of bad news but every 91-97 ECU will eventually fail. First three links after google-ing "electrolytic capacitors lifespan" http://www.elna-america.com/tech_al_reliability.php http://www.eng-tips.com/viewthread.c...=178825&page=1 http://www.hans-egebo.dk/Tutorial/el...capacitors.htm |

| Back | Home | Forward |