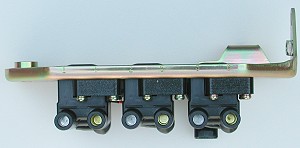

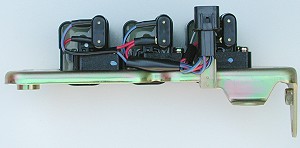

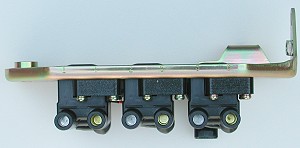

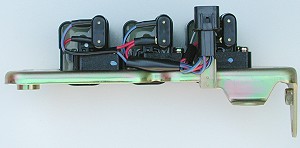

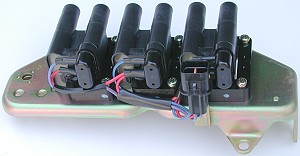

Three ignition coils are used in the distributorless ignition system on the Mitsubishi 3000GT and Dodge Stealth DOHC engine (turbo and non-turbo). Each ignition coil fires a pair of spark plugs simultaneously: one with the piston before TDC on the compression stroke and the other one with the piston before TDC on the exhaust stroke. The spark during the exhaust stroke is wasted and the basically inert exhaust gas does not combust. This is called a wasted spark ignition system (see my web pages 2-sparkplugtech.htm for more information on spark plugs and 2-timing.htm for information on timing events).

Three ignition coils are used in the distributorless ignition system on the Mitsubishi 3000GT and Dodge Stealth DOHC engine (turbo and non-turbo). Each ignition coil fires a pair of spark plugs simultaneously: one with the piston before TDC on the compression stroke and the other one with the piston before TDC on the exhaust stroke. The spark during the exhaust stroke is wasted and the basically inert exhaust gas does not combust. This is called a wasted spark ignition system (see my web pages 2-sparkplugtech.htm for more information on spark plugs and 2-timing.htm for information on timing events).

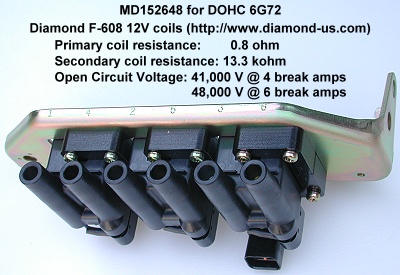

| Primary coil resistance: | ~0.8 ohm | |

| Secondary coil resistance: | ~13,300 ohm | |

| Open Circuit Voltage: | 41,000 V @ 4 break amps | |

| 48,000 V @ 6 break amps |

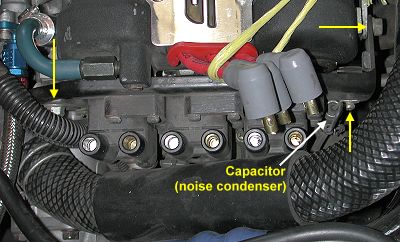

1. Primary coil resistance. Before you start, switch the digital VOM to measure resistance and touch the two leads together. Note the value indicated (mine said 0.6 ohms) and subtract this value from the next three measurements. If using an analog VOM meter, use the zeroing dial for the resistnace setting to eliminate the offset. Connect the VOM positive lead to terminal [3] in the harness connector on the coils bracket. Measure the resistance between between terminal [3] and the remaining terminals by connecting the VOM negative (ground) lead sequentially to terminals [1], [2], and [4]. Note that terminals [1] and [2] are near the release lever catch and terminals [3] and [4] are near the smooth side of the connector. The service manuals indicate a standard value of 0.67 to 0.81 ohms. All of my old (65,000 miles and 11 years) and new ignition coils measured 0.8 ohms (1.4 minus 0.6 ohms).

1. Primary coil resistance. Before you start, switch the digital VOM to measure resistance and touch the two leads together. Note the value indicated (mine said 0.6 ohms) and subtract this value from the next three measurements. If using an analog VOM meter, use the zeroing dial for the resistnace setting to eliminate the offset. Connect the VOM positive lead to terminal [3] in the harness connector on the coils bracket. Measure the resistance between between terminal [3] and the remaining terminals by connecting the VOM negative (ground) lead sequentially to terminals [1], [2], and [4]. Note that terminals [1] and [2] are near the release lever catch and terminals [3] and [4] are near the smooth side of the connector. The service manuals indicate a standard value of 0.67 to 0.81 ohms. All of my old (65,000 miles and 11 years) and new ignition coils measured 0.8 ohms (1.4 minus 0.6 ohms).

2. Secondary coil resistance. Leaving the VOM set to measure resistance, connect the positive and negative leads to the metal parts inside the two high-voltage terminals on a coil. Repeat for all three coils. The standard value is 11,300 to 15,300 ohms. My old coils measured 13,910, 13,820, and 13,410 ohms for coils A, B, and C, respectively. The new coils measured 13,310, 13,340, and 13,200 ohms for coils A, B, and C, respectively.

2. Secondary coil resistance. Leaving the VOM set to measure resistance, connect the positive and negative leads to the metal parts inside the two high-voltage terminals on a coil. Repeat for all three coils. The standard value is 11,300 to 15,300 ohms. My old coils measured 13,910, 13,820, and 13,410 ohms for coils A, B, and C, respectively. The new coils measured 13,310, 13,340, and 13,200 ohms for coils A, B, and C, respectively.

| Back | Home | Forward |